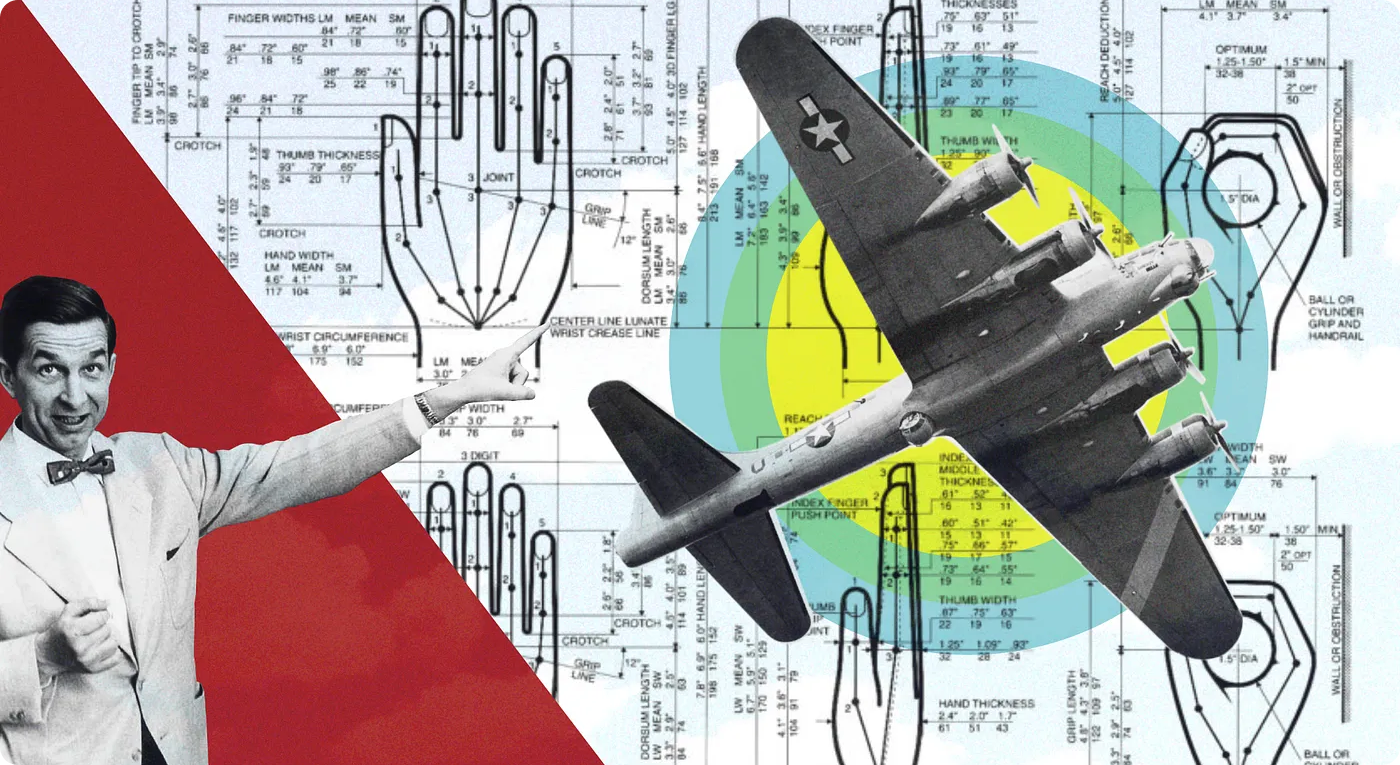

As the massive B-17 ‘Flying Fortress’ touched down after a long day of combat, the pilot flicked the control to drop his speed as he had always done. Within seconds, the massive plane collapsed onto the tarmac, skidding and screaming on its fuselage.

These accidents were to happen with increasing frequency during the first years of World War II and the U.S. Army Air Forces were getting desperate. How did experienced flyers, who practically lived in their planes for hours on end, make such basic errors of judgment?

The B-17 was no ordinary plane, being used for daylight strategic bombing against German industrial and military targets in World War II. In 1941, with the war effort intensifying, they rushed the plane into service, holding the record for the largest production rate of any aircraft for many years. From an aesthetic point of view, the B-17 was a beautifully designed plane and a model for many generations of bombers and large aircraft to come. It became a darling of the war effort and a most powerful symbol for Americans to rally behind, yet behind the scenes, these early models were experiencing embarrassing and fatal accidents.

Crashed B-17 on runway

Unable to discover the root cause of the accidents and under pressure, the Army Air Forces assigned a young psychologist, Alphonse Chapanis, to investigate this spate of ‘pilot error’. He had just graduated from Yale in 1943 as a psychologist and he had a particular interest in the interaction between humans and design, considering their behaviour and characteristics. This was a major challenge for any newbie.

He would work alongside the brilliant psychologist Paul Fitts, who was already a star and was leading the Army Air Force Aviation Psychology Program at Wright-Patterson Air Field. That same Paul Fitts would go on to develop the famous Fitts’ Law, which became one of the most successful models of human motion and a basic principle all aspiring product designers learn.

Designer error

Chapanis began interviewing pilots who had crashed B-17s and B-25s and a pattern emerged that turned his attention to the controls within the cockpit. As Fitts said ‘the intense effort to produce new weapons, the race against time in industrial production, and the magnitude of the program required to train men to operate these new machines resulted inevitably in many instances in which the final man-machine combination failed to function effectively.’ ¹

What Chapanis found when inspecting the cockpits of these planes were two identical toggle switches side by side, one for the landing gear, the other for the landing flaps. These controls were also similar in size and shape.

B-17 cockpit with the offending gear and wing flap controls. Red metal channels were added in later models.

As a weary pilot was landing, under ‘the stress of landing after combat’, thinking he was controlling the wing flaps to control speed, would accidentally reach for the landing gear and retract the plane’s wheels on landing, causing an obvious catastrophe. ‘Pilot error’ had now become ‘Designer error’. Think about when you put your palm on a gear shift of a car (if you live in Europe), you rely on the shape and size to tell you haven’t reached for the handbrake.

Original cover B-17 Pilot’s Manual and complex checklist (courtesy of the AirCorps Library)

Contrast

Without contrast, elements would have the same intensity. The essence of an element is defined by its value, properties, or quality of this element relative to something else. This idea feels so intuitive as to be stupidly obvious. Yet think about the many times you have scrolled to the end of an online tax form only to see two buttons with the same colour, message, or size. Even though you read the button text carefully, the function of the button may still be vague. In the pressure of getting an unpleasant job done, which button should you try first? The size, and strength of colour are all cues as to the hierarchy of the call to action.

Think about what this means for a job with a thousand times more pressure, anxiety, and stress. We can at least do taxes from the comfort of our homes. The design decision to put two controls with differing functions that were visually similar and close together seems odd now, yet these early plane designers had no training in human factors and pilots had never been pushed to the limit like this before.

Shape coding

Unable to move controls further apart on existing aircraft because of manufacturing constraints, Chapanis introduced the beautifully elegant solution of shape coding.

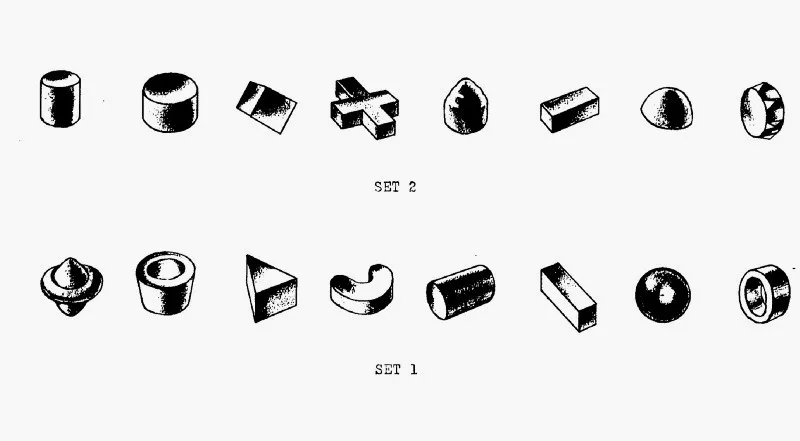

Investigation of tactual discriminability of knob shapes by the Aero Medical Laboratory ²

He modified the landing gear control by adding a wheel-shaped knob and a wedge-like shape to the wing flap control. Now pilots could feel and easily map the shape to the intended purpose. Stanley N. Rosco says that “it is a reasonably safe guess that the first time anyone intentionally or unknowingly applied a psychological principle to solve a design problem in airplanes occurred during the war, and it is possible that the frequent wheels-up-after landing mishaps in certain airplanes were the first such case.” ³

Accidents dropped to zero overnight. Chapanis had solved a real life and death issue with one brilliant insight. In further versions of the aircraft, designers fitted spring-loaded covers to the landing gear control to prevent the gear from being engaged unless the wing flaps were raised and a red metal channel around the wing flap control to distinguish it further.

Founding fathers

Chapanis and Fitts discovered poor design patterns that were used without modification across many models of aircraft. Without their insight, these flaws might have been replicated further. Both were founding fathers of ergonomics, a field that would have an enormous impact on user experience and product design.

The principle of contrast solved a life and death issue, highlighting that when there are many options, marking them clearly as distinct is crucial, and when two buttons do radically different things, making them visually different is paramount. It sounds obvious in hindsight, yet we can easily overlook it in the heat of design.

References

Many thanks to the members of ww2aircraft.net for details of the B-17 control layout and access to plans.

Alphonse Chapanis, The Chapanis Chronicles: 50 Years of Human Factors Research, Education, and Design

AirCorps Library, WWII Era Military Blueprints & Manuals

[1] Kim Vicente, The Human Factor: Revolutionizing the Way We Live with Technology

[2] Wright Air Development Center, The coding of aircraft controls, 1953

[3] Stanley N. Roscoe, The Adolescence of Engineering Psychology, 1997